|

Building

the Bat Car

Fabrication of steel

windshield frame

|

-

Fabrication

and mounting of the

bat fins.

-

Engine Cover and

hinge mounting

-

Complete re wiring

-

Fabrication of steel

windshield frame

-

Fabrication and

construction of

Convertible

Top

-

Fabrication of back

window

-

Fabrication of Front

Beam support

structure

-

Fabrication of Gull

Wing Doors

-

Constructing

retractable

Headlights

-

Mounting and fitting

of front turn signal

lights

-

Mounting and fitting

of Gas Tank

-

Fabrication and

installation of side

scoops

-

Fabrication

of a 2"body lift

Fabrication of steel

windshield frame.

The

original Bradley GT was

never designed to be a

convertible. The

windshield frame and "T"

top were one solid piece

with a wooden frame

imbedded into the

fiberglass. The

windshield frame was

made to fit a 1964 to

1967 Corvette coup

windshield glass. I

wanted to make a

removable "T" top using

draw latches. so first

thing was to cut the

windshield frame from

the "T" top. I did this

using a saber saw. Then

I used a Dremmel cutting

wheel to cut through the

inside layer of

fiberglass. I then pried

out all the wooden

supports in the

windshield frame.

I got a

1/2 "x1"x 20'

piece of steel bar and

cut and shaped to fit

the pillars on each side

of the windshield frame.

I cut a 3/4 "x 1 1/4"

square hole in the dash

on each side for the

steel pillar to go down

into the wheel well

about 10 inches. I then

formed two pieces of

steel to fit inside the

top if the fiberglass

frame. I welded the

pillars to the top

frame. I welded in the "pin" half of the draw

latch into the center of

the windshield frame for

a point to connect the

"T" top later.

I then

made brackets out of

.090 sheet steel and

drilled and tapped the

holes in the windshield

frame side mounts to fit

a 1/2 "-13 thread bolt.

The fabricated brackets

were mounted on the body

side of the wheel wells

to hold the windshield

frame.

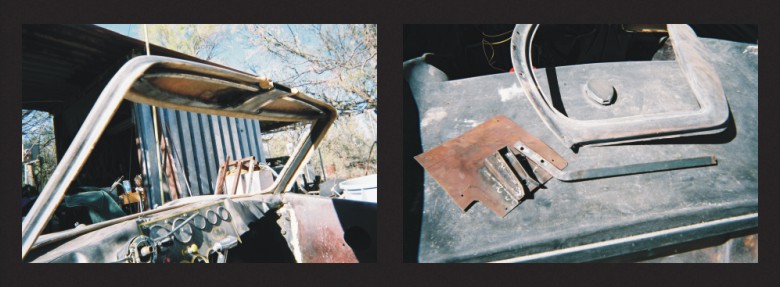

The below photos were

taken looking up inside

the wheel well. The

photo on the left shows

the square windshield

frame hole and the two

1/2" holes that the

bolts will go through to

bolt the windshield

frame to the bracket.

The photo below on the

right shows the bracket

fiber glassed and screwed

to the inside of the wheel

well. This proved to be

a very strong way to

mount the windshield and

still make it removable

when needed.

The below photos were

taken looking up inside

the wheel well. The

photo on the left shows

the square windshield

frame hole and the two

1/2" holes that the

bolts will go through to

bolt the windshield

frame to the bracket.

The photo below on the

right shows the bracket

fiber glassed and screwed

to the inside of the wheel

well. This proved to be

a very strong way to

mount the windshield and

still make it removable

when needed.

Once the

steel frame was fitted

to the inside of the

fiberglass frame, the

windshield mount bracket was glued in place

using fiberglass matt

and resin. Once the

frame was adhered to the

steel frame, the whole

assembly was removed,

turned upside-down and

whole cavity was filled

layer after layer of

fiber glass and resin

until the windshield

frame was filled solid.

NOTE: Always have the

windshield glass on hand

and make sure when you

make the steel frame

that the fiberglass

pinch molding fits the

Corvette windshield

glass shape. My

fiberglass windshield

frame had about a 3/8"

sag in the middle and

when I went to install

the glass, I could not

use the Corvette

windshield rubber with

out cracking the glass.

I had to have it

installed with RTV

Silicone.

|

After

the resin cured,

everything was

sanded smooth. and

the frame was

re-mounted back on

the car.

After

the windshield frame

was re-mounted I

adjusted the draw

latch so the "T" top

would fit correctly.

It was a lot of work

but the windshield

frame is so strong

you can pull

yourself up out of

the car with out

cracking the

windshield glass.

And people do tend

to use the

windshield to help

themselves out of

the car.